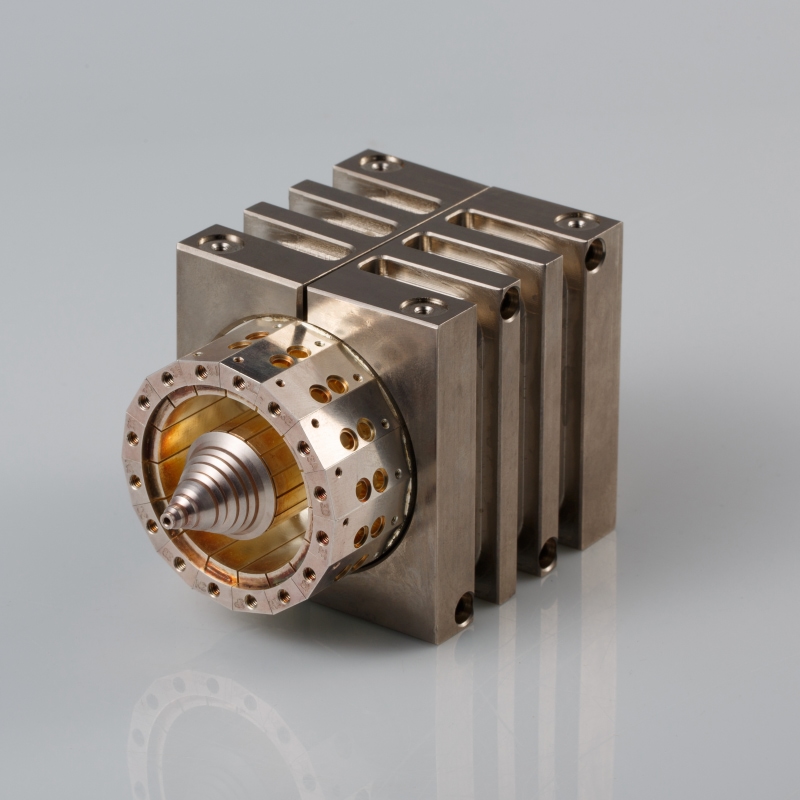

2019 wholesale price Custom Aluminum Stainless Steel Brass Copper Precision CNC Lathe Machining Component

No matter new customer or old customer, We believe in long term and trusted relationship for 2019 wholesale price Custom Aluminum Stainless Steel Brass Copper Precision CNC Lathe Machining Component, We sincerely welcome equally overseas and domestic business partners, and hope to operate along with you during the close to foreseeable future!

No matter new customer or old customer, We believe in long term and trusted relationship for China CNC Lathe and CNC Lathe Machining, Welcome any of your inquiries and concerns for our items. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We have been the first business partner in your case!

Available materials:

Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10: Stainless steel 304 is the most common stainless steel. It is essentially non-magnetic steel and it is less electrically and thermally conductive than carbon steel. It is wildly used because it easily formed in various shapes. It is machinable and weldable. Other names for this steel are: A2 stainless steel, 18/8 stainless steel, UNS S30400, 1.4301. 304L stainless steel is the low carbon version of stainless steel 304.

Stainless steel 316/316L | 1.4401/1.4404 | X2CrNiMo17-12-2: The second most used stainless steel after 304, the general purpose austenitic stainless steel 316 has superior corrosion resistance particularly in chloride containing environments and good elevated temperature strength. The low carbon version 316L has even better corrosion resistance in welded structures.

Stainless steel 303 | 1.4305 | X8CrNiS18-9: Grade 303 is the most readily machineable of all the austenitic grades of stainless steel. It is basically the machining modification os stainless steel 304. This property is due to the higher sulphur presence into the chemical composition. The sulphur presence improves the machinability but slightly lower the corrosion resistance and the toughness compared to the one of stainless steel 304.

Specification of stainless steel

Stainless steel is a type of steel alloy made from a combination of iron and at least 10.5% chromium. It is highly resistant to corrosion, making it suitable for a variety of applications, including medical, automation industrial and food service. The chromium content in stainless steel gives it several unique properties, including superior strength and ductility, excellent heat resistance and non-magnetic properties. Stainless steel is available in a wide range of grades, each with different properties to suit different applications. As a CNC machining machine shop in China. This material use widely in machined part.

Advantage of stainless steel

1. Durability – Stainless steel is a very hard and durable material, making it resistant to dents and scratches.

2. Corrosion Resistance – Stainless steel is corrosion-resistant, meaning it won’t corrode or rust when exposed to moisture or certain acids.

3. Low Maintenance – Stainless steel is very easy to clean and maintain. It can be wiped down with a damp cloth and doesn’t require any special cleaning solutions or polishes.

4. Cost – Stainless steel is generally more cost-effective than other materials such as marble or granite.

5.Versatility – Stainless steel can be used for a variety of applications, both indoors and outdoors. It’s also available in a variety of finishes and styles, making it a great choice for any home.”

High tensile strength, corrosion and temperature resistant. Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished in cnc machine services.

| Stainless steel 304/304L | 1.4301 | X5CrNi18-10 |

| Stainless steel 303 | 1.4305 | X8CrNiS18-9 |

| Stainless steel 440C | 1.4125 | X105CrMo17 |

How Stainless steel in CNC machining parts

Stainless steel is a popular choice for CNC machining parts because of its durability, strength, and corrosion resistance. It can be machined to tight tolerances and is available in a variety of grades and finishes. Stainless steel is used in a range of industries, as rapid prototype from medical to aerospace, and is ideal for applications requiring a high level of durability and corrosion resistance.”

What CNC machining parts can use for stainless steel material

The most common CNC machining parts for stainless steel materials include:

What kind of surface treatment is suitable for CNC machining parts of stainless steel material

The most common surface treatments for CNC machining parts of stainless steel material are sandblasting, passivation, electroplating,Black oxide, Zinc plating,Nickle plating,Chrome plating,Powder coating, QPQ and painting. Depending on the specific application, other treatments such as chemical etching, laser engraving, bead blasting and polishing may also be used.

CNC machining , miling , turning , drilling , tapping , wire cutting , tapping , chamfering , surface treatment ,etc.

The products shown here is only to present the scope of our machining business activities.

We can custom according to your parts drawings or samples.”

Contact Us

No matter new customer or old customer, We believe in long term and trusted relationship for 2024 wholesale price Custom Aluminum Stainless Steel Brass Copper Precision CNC Lathe Machining Component, We sincerely welcome equally overseas and domestic business partners, and hope to operate along with you during the close to foreseeable future!

2024 wholesale price China CNC Lathe and CNC Lathe Machining, Welcome any of your inquiries and concerns for our items. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We have been the first business partner in your case!