Aluminum Turned Parts: A Key Component in Modern Manufacturing

Precision at Its Core: CNC Turned Components

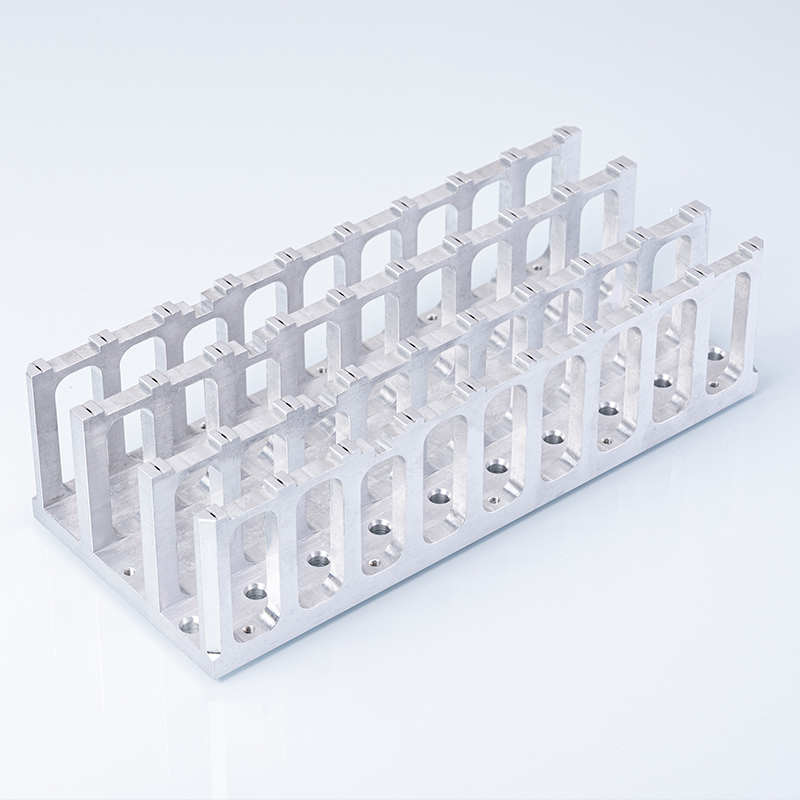

The heart of aluminum turned parts lies in CNC turned components. Employing computer numerical control (CNC) technology, manufacturers achieve unparalleled accuracy and repeatability. These CNC turned components not only meet but often exceed the exacting standards demanded by various industries. The intricate designs and tight tolerances of high precision parts are made possible through the expertise in CNC machining aluminum parts.

The Aluminum Advantage: Precision Machining

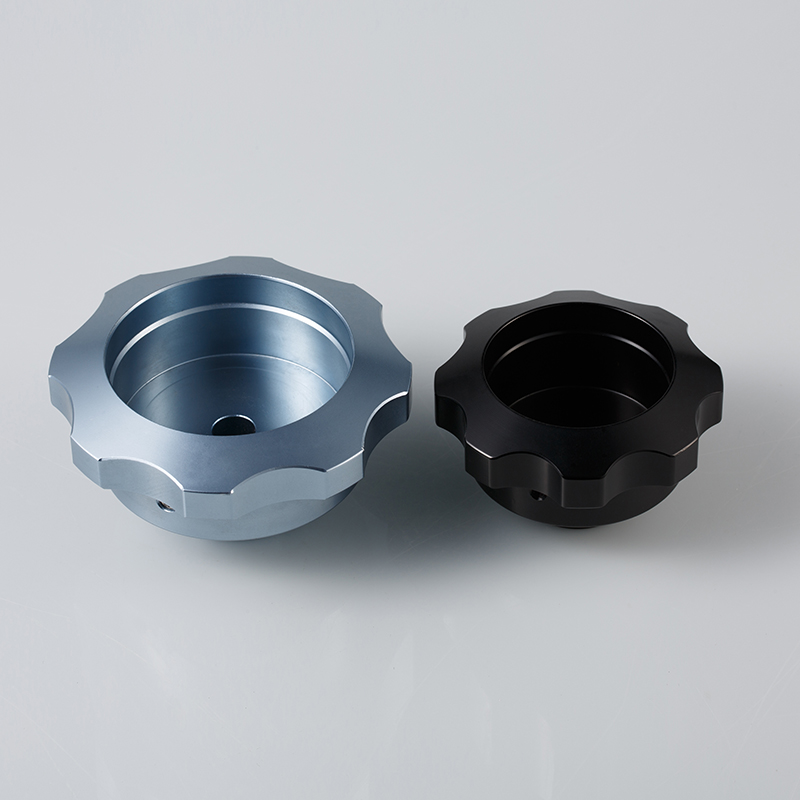

Aluminum, known for its lightweight yet robust properties, is the material of choice in many applications. Its adaptability to precision machining processes makes it a preferred option for manufacturing. The process of aluminum precision machining involves a symphony of actions, including turning, milling, and 5-axis CNC machining. This ensures the creation of intricate and complex aluminum turned parts that meet the rigorous specifications of contemporary industries.

Meeting Industry Demands: 5-Axis CNC Parts

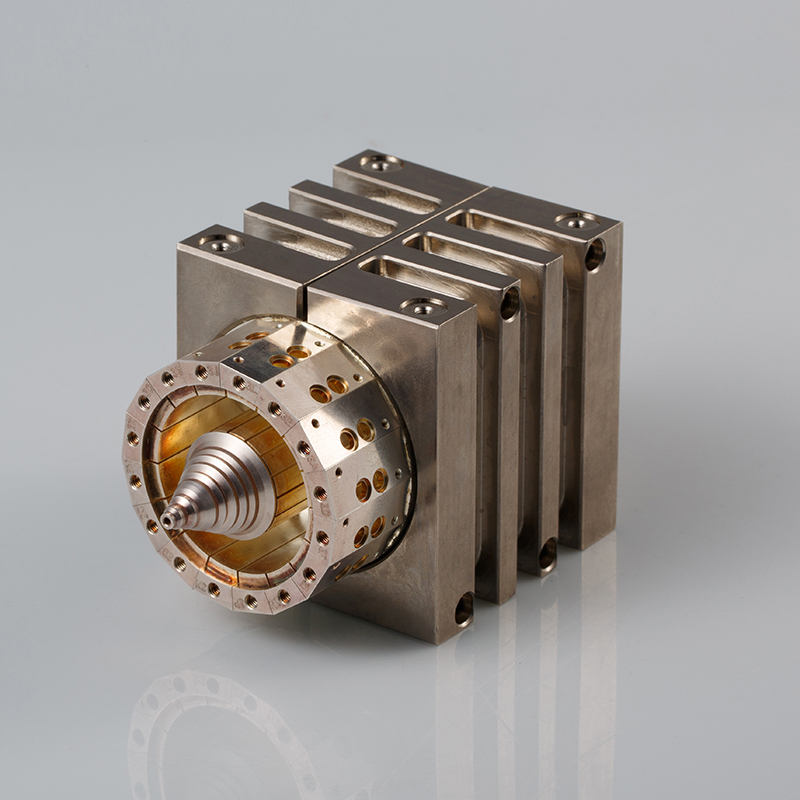

5-axis CNC machining has emerged as a game-changer in the world of precision manufacturing. This advanced technique allows for the creation of complex shapes and intricate geometries with remarkable accuracy. Aluminum turned parts produced using 5-axis CNC technology have found applications in fields where every micron of precision counts, such as the aerospace and medical industries.

Excellence in Execution: Meeting the Challenge

The production of aluminum turned parts demands not only technical expertise but also a relentless pursuit of perfection. The synergy between CNC turned components, high precision parts, and aluminum precision machining is where the magic happens. Meeting the challenge of modern manufacturing requires a commitment to continuous improvement, an unwavering focus on quality, and the ability to adapt to evolving industry requirements.

A Glimpse into the Future: Aluminum Turned Parts

In the aerospace sector, there is a constant demand for unique, customized solutions. Custom CNC components provide tailored responses to intricate challenges. These components are designed with a focus on innovation, enabling adaptability and ingenuity in aerospace engineering.

The Crucial Role of Precision Machine Components

As manufacturing evolves, aluminum turned parts will continue to play a pivotal role in shaping the future. The demand for precision components, the growth of innovative technologies, and the ever-expanding applications of aluminum in different industries are driving the industry forward. Aluminum turned parts are not merely components; they are the embodiment of precision, excellence, and the future of modern manufacturing.

In conclusion, aluminum turned parts represent the culmination of precision, technology, and expertise in modern manufacturing. From CNC turned components to high precision parts and 5-axis CNC parts, these components are the unsung heroes behind many technological advancements. As industries continue to evolve, aluminum turned parts will remain a key component and an emblem of precision in the manufacturing landscape.