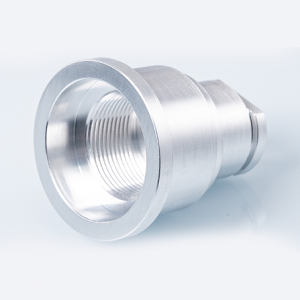

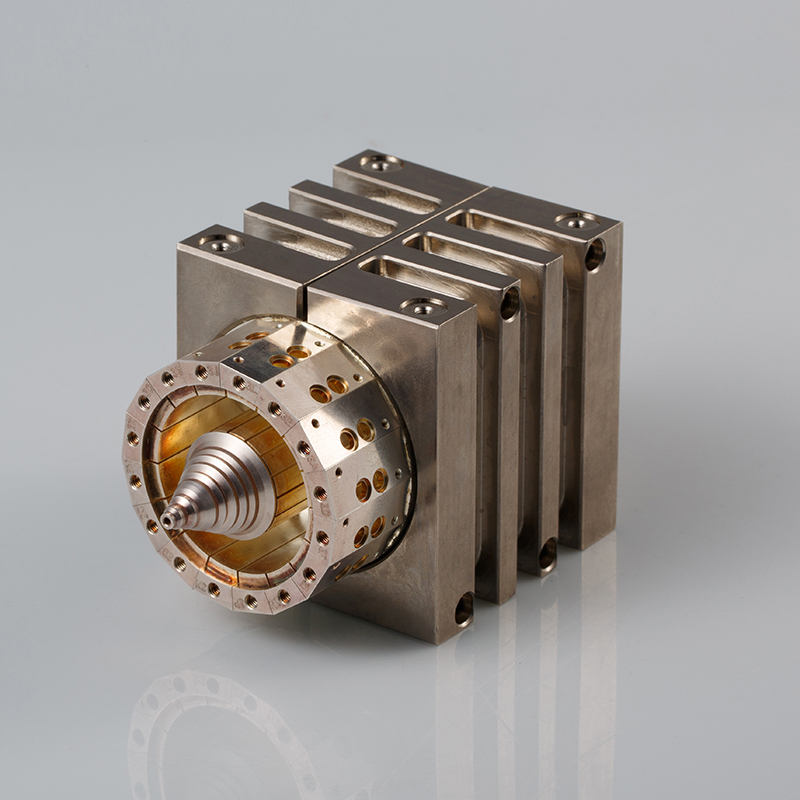

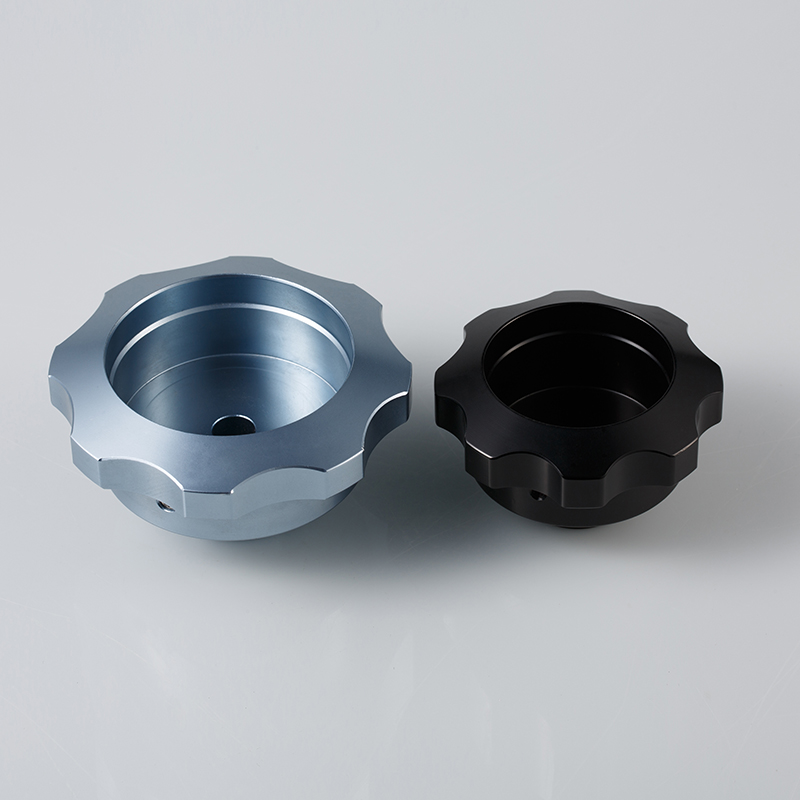

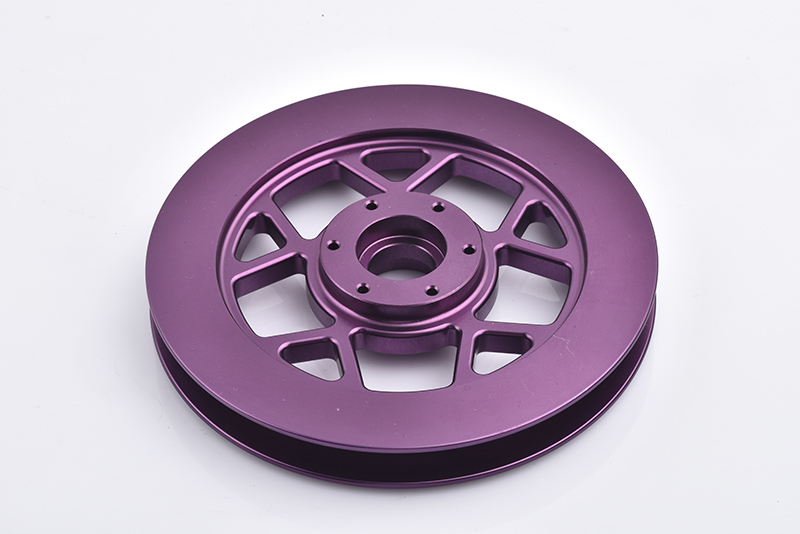

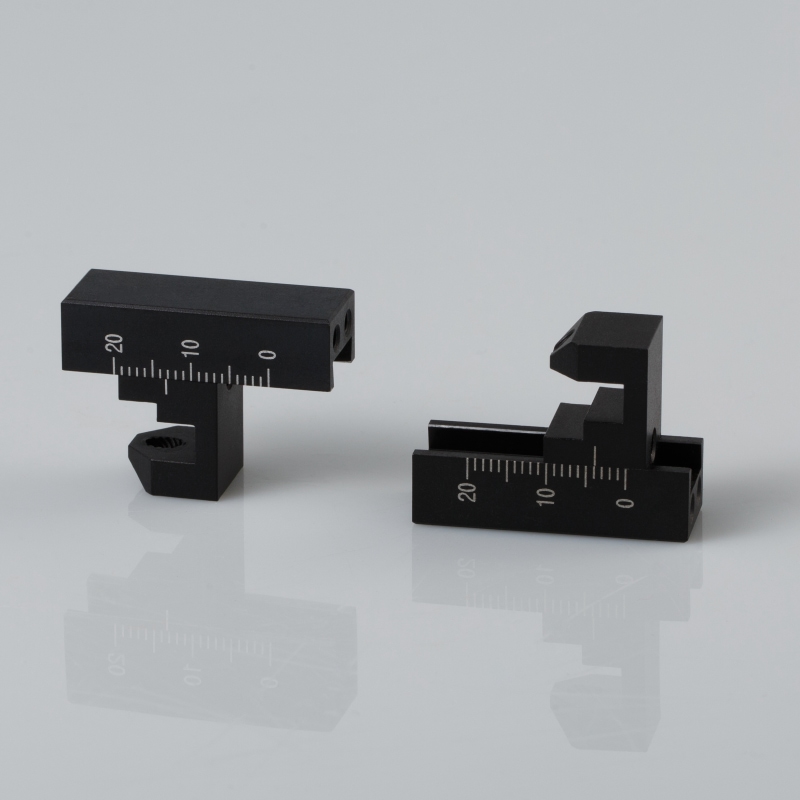

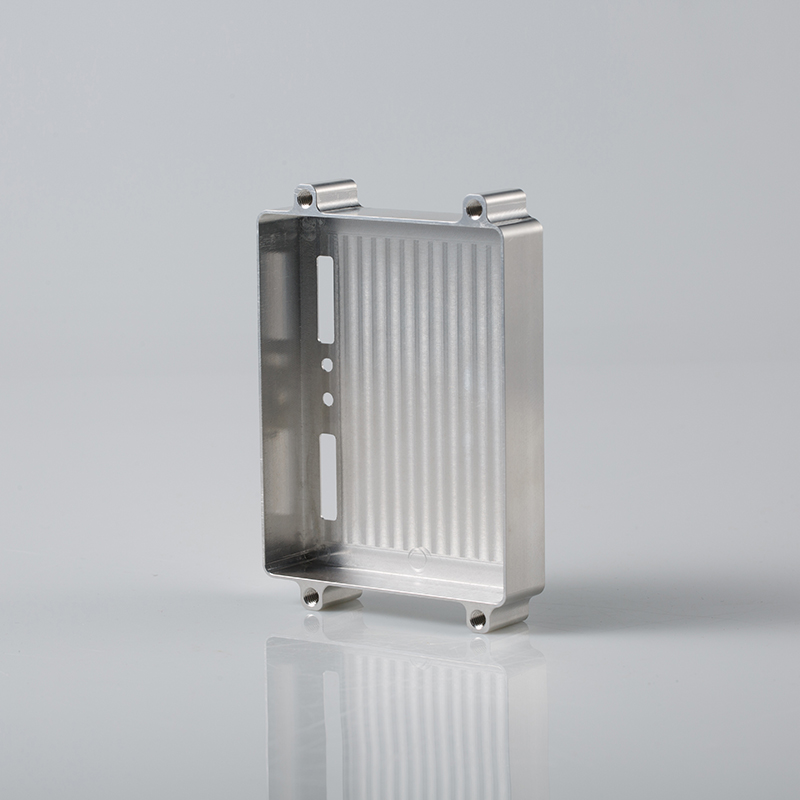

Manufacturing Of Custom Aluminum Parts

Professional Aluminum Machining Team

Our team of professional aluminum machining experts has the skills and experience necessary to provide the highest quality aluminum machining services. We specialize in CNC machining, milling, and turning, and can offer a variety of services such as drilling, tapping, sanding, and honing. We use the latest technology and are experienced in working with a variety of materials and alloys. Our team works closely with clients to ensure that their aluminum machining needs are met.

Manufacturing Of Custom Aluminum Parts

Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCu: This grade of aluminum is also know as aircraft or aerospace aluminum due its most common application. The dominant element of 7075 alloys is zinc. Its high strength makes is stand out from the other aluminium alloys and be comparable to the strength of many steels. Even though it has convinent combination of properties for many applications, 7075-T6 compared to other aluminium alloys has lower corrosion resistance, but very good machinabilit.

Aluminum 6082 | 3.2315 | 64430 | AlSi1MgMn: 6082 is famous for its excellent corrosion resistance, high strength - the highest of the 6000 series alloys which makes it highly used in stressed applications.. As a relatively new alloy it can replace 6061 in many applications. It is a common material for machining, even though it is difficult to produce thin walls.

Aluminum 5083-H111 | 3.3547 | 54300 | AlMg4.5Mn0.7: 5083 aluminium alloy is a good choice for extreme environments due to its resistivity to salty water, chemicals, attacks. It has relatively high strength and good corrosion resistance. This alloy stands out because it is not hardenable by heat treatment. Due to its high strength it has limited complexity of shapes that can be machined, but it has excellent weldability.

Aluminum MIC6: MIC-6 is a cast aluminum plate that is a blend of different metals. It provides excellent accuracy and machinability. MIC-6 is produced by casting which results in stress relieving properties. Additionally, it is light weight, smooth and free from tension, contaminants and porosity.

Aluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5: Aluminum 5052 alloy is high magnesium alloys and like all 5000-series has a fairly high strength. It can be hardened to a significant degree by cold working, therefore enabling a series of “H” tempers. However, it is not heat treatable. It has good corrosion resistance, especially to salt water.