In the ever-evolving world of CNC machining, the demand for precision in milling long parts has seen a significant rise, particularly within the medical, aerospace, and oil & gas industries. LAIRUN Precision Manufacture Technology Co., Ltd. is at the forefront of meeting this demand, leveraging cutting-edge technology to ensure high accuracy, consistency, and efficiency in every machined part.

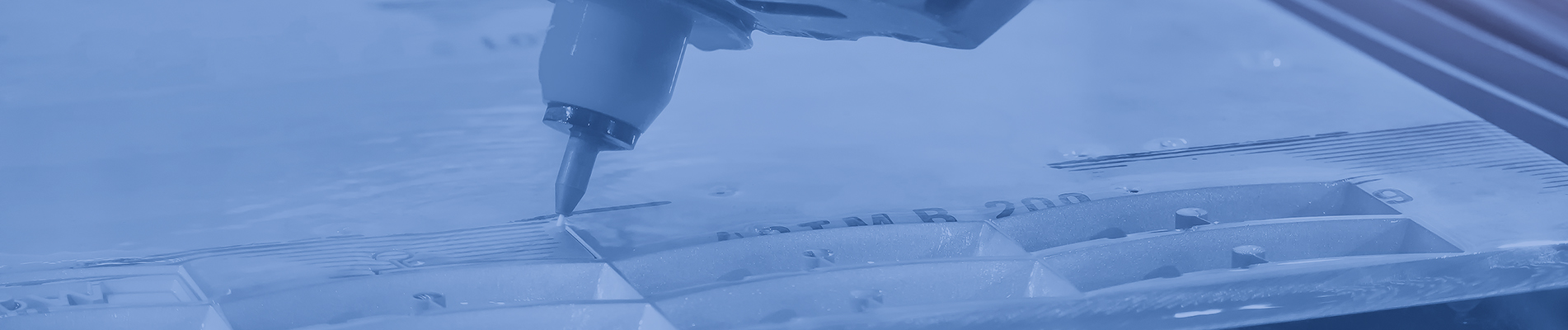

Milling long parts presents unique challenges, such as maintaining tight tolerances across extended lengths, minimizing deflection, and ensuring surface finish quality. LAIRUN’s advanced 5-axis CNC milling machines are engineered to address these challenges head-on. Our equipment is designed to handle complex geometries and long workpieces with unparalleled precision, ensuring that even the most intricate designs are executed flawlessly.

The company’s expertise in milling long parts is complemented by its commitment to using only the highest quality materials, including various grades of stainless steel, titanium, and high-performance alloys. This capability is critical in sectors where reliability and durability are non-negotiable, such as medical device manufacturing and energy exploration.

Additionally, LAIRUN’s investment in state-of-the-art CAM software allows for optimized tool paths, reducing cycle times and enhancing overall productivity. This software also facilitates real-time adjustments during the milling process, ensuring that each part meets exact specifications and reduces the risk of errors.

As industries continue to push the boundaries of what’s possible in precision machining, LAIRUN remains dedicated to innovation and excellence. Our focus on milling long parts with high precision not only meets but exceeds the stringent requirements of today’s demanding markets.

For more information on how LAIRUN can support your machining needs, especially in milling long parts, please contact our team of experts today.

Post time: Aug-22-2024