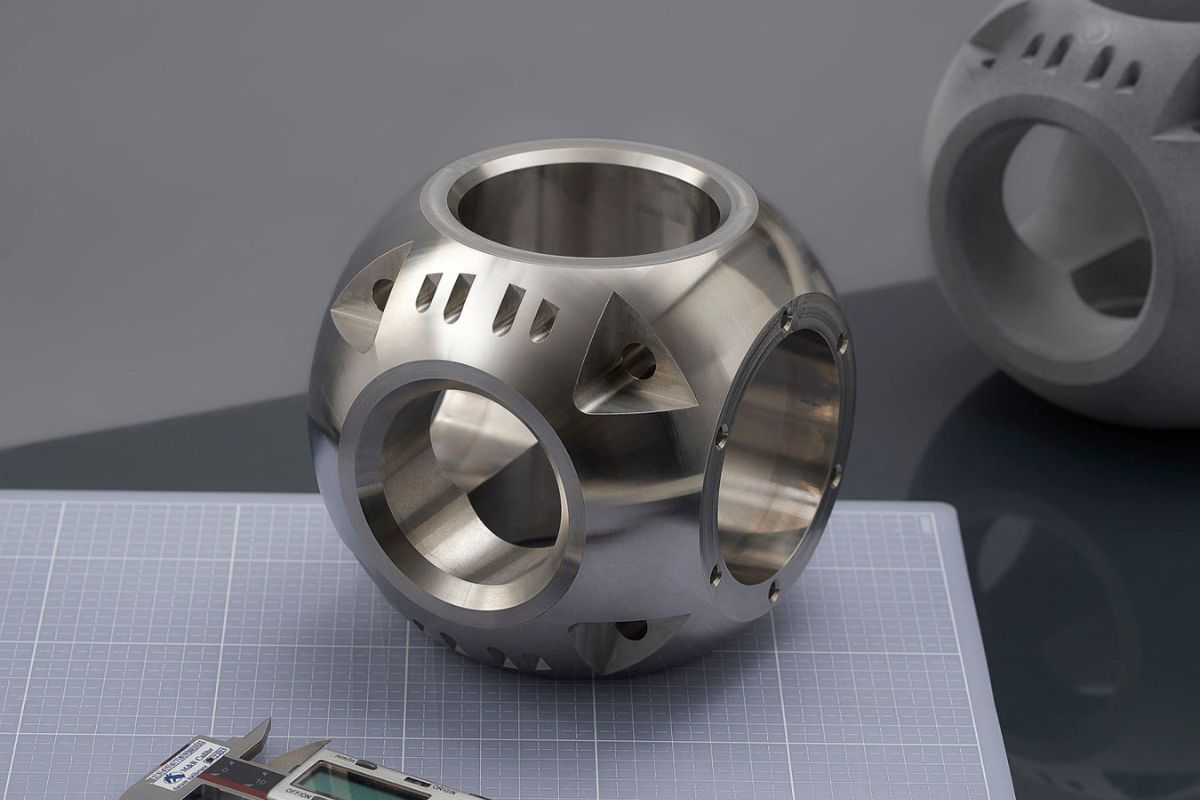

In the fast-paced world of product development, precision prototype machining is essential for transforming concepts into tangible, high-quality components. At LAIRUN, we specialize in manufacturing high-precision prototypes that meet the strictest industry standards, ensuring seamless transitions from design to production.

Our state-of-the-art CNC machining technology enables us to produce complex prototypes with tight tolerances, delivering exceptional accuracy, surface finish, and functionality. Whether you need metal or plastic prototypes, our advanced machining processes, including CNC milling, turning, and EDM machining, ensure that every part meets your exact specifications.

Why Choose Precision Prototype Machining?

1.Speed & Efficiency – Our rapid machining capabilities allow for quick turnaround times, helping you test and refine your designs faster.

2.Uncompromising Accuracy – We achieve tight tolerances up to ±0.005mm, ensuring precision in every detail.

3.Versatile Material Options – We work with a wide range of materials, including aluminum, stainless steel, titanium, brass, engineering plastics, and more.

4.Cost-Effective Prototyping – Our flexible manufacturing solutions allow for both one-off prototypes and small-batch production, optimizing costs without compromising quality.

At LAIRUN, we understand the importance of functional prototypes in industries such as medical, robotics, aerospace, and precision instrumentation. Our engineering team works closely with clients to refine designs, identify potential improvements, and ensure that prototypes meet performance requirements before full-scale production.

With a commitment to excellence, innovation, and precision, we provide high-quality prototype machining solutions that help companies bring their ideas to market with confidence.

Contact LAIRUN today to discuss your precision prototype machining needs and discover how our expertise can support your next project!

Post time: Mar-21-2025