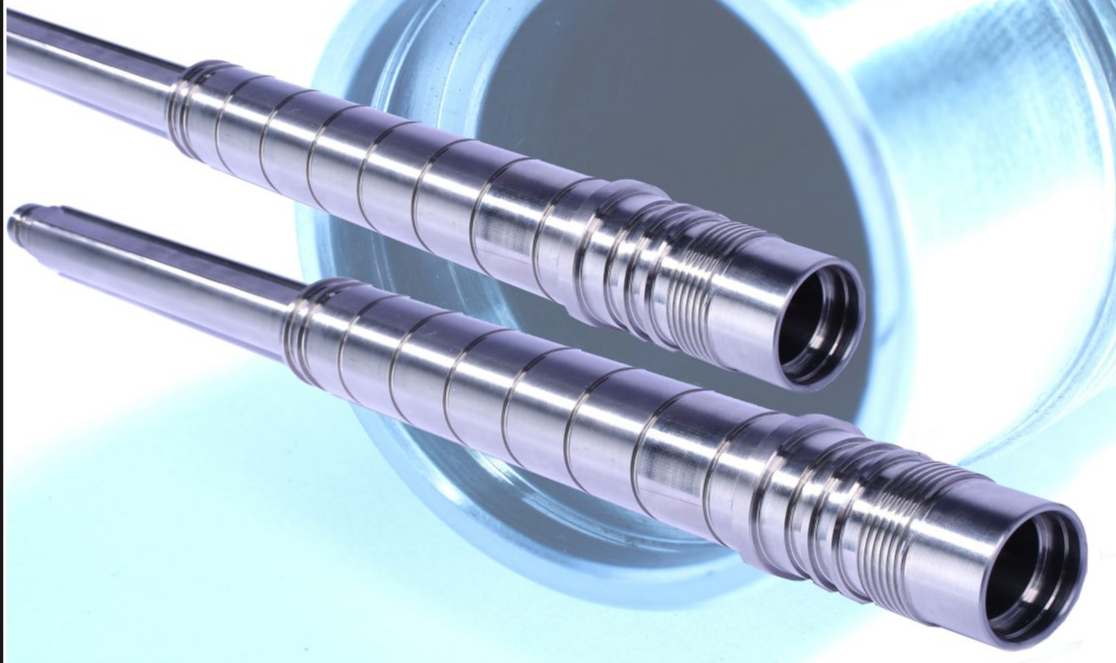

At LAIRUN, we take pride in our precision machining capabilities, particularly when working with high-performance materials like Inconel alloy. Inconel alloys are renowned for their exceptional high-temperature strength, corrosion resistance, and durability, making them ideal for a range of demanding applications across various industries.

Our extensive experience and advanced technology enable us to deliver high-quality machining services for several key types of Inconel alloys:

● Inconel 625: Widely used in the oil and gas, aerospace, and chemical industries, Inconel 625 is known for its excellent corrosion resistance and oxidation resistance, making it a top choice for harsh environments.

● Inconel 718: This alloy is frequently utilized in the aerospace and oil industries due to its high strength and good weldability. Inconel 718 is essential for components that require high strength and thermal stability.

● Inconel 600: Commonly found in aerospace and chemical industries, Inconel 600 offers high-temperature strength and resistance to corrosion, making it suitable for a variety of demanding applications.

● Inconel 690: Primarily used in the chemical industry, Inconel 690 excels in high-temperature corrosive environments, providing reliable performance in extreme conditions.

Here’s what sets us apart in the specialized field of Inconel alloy machining:

1. Advanced Machining Equipment

We utilize state-of-the-art CNC machining centers, precision grinding machines, and high-performance EDM machines to meet the stringent requirements of Inconel alloy machining. Our equipment is designed to handle the complexities of working with these advanced materials.

2. Skilled Engineering Team

Our team of experienced engineers possesses a deep understanding of Inconel alloys and their unique properties. Their expertise allows us to tackle intricate machining challenges and deliver high-precision components for a range of industries.

3. Rigorous Quality Control

We follow a stringent quality management system to oversee every phase of the machining process. From selecting raw materials to final inspections, we ensure that our products adhere to the highest standards.

4. Customized Solutions

We offer tailored machining solutions to meet the specific needs of our clients. Whether facing a unique design challenge or a complex engineering requirement, we work closely with clients to provide effective and innovative solutions.

Our dedication to excellence in Inconel alloy machining has earned us recognition for delivering reliable and high-quality components. We look forward to continuing our efforts and exploring new opportunities for collaboration.

Contact Us to learn more about our Inconel alloy machining services and how we can support your next project.

Post time: Jul-10-2024