The Growing Significance of Aluminum Precision Parts

Precision Beyond Imagination

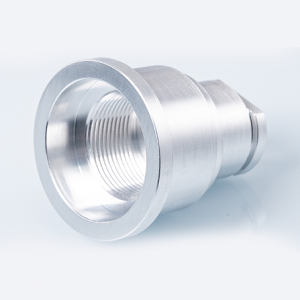

At the heart of this transformation lies the remarkable precision achieved with aluminum precision parts. These components are meticulously crafted to meet the most demanding specifications, offering a level of accuracy that was previously unimaginable. This precision extends across diverse sectors, including aerospace, automotive, electronics, medical devices, and more.

Aerospace: Where Every Micron Matters

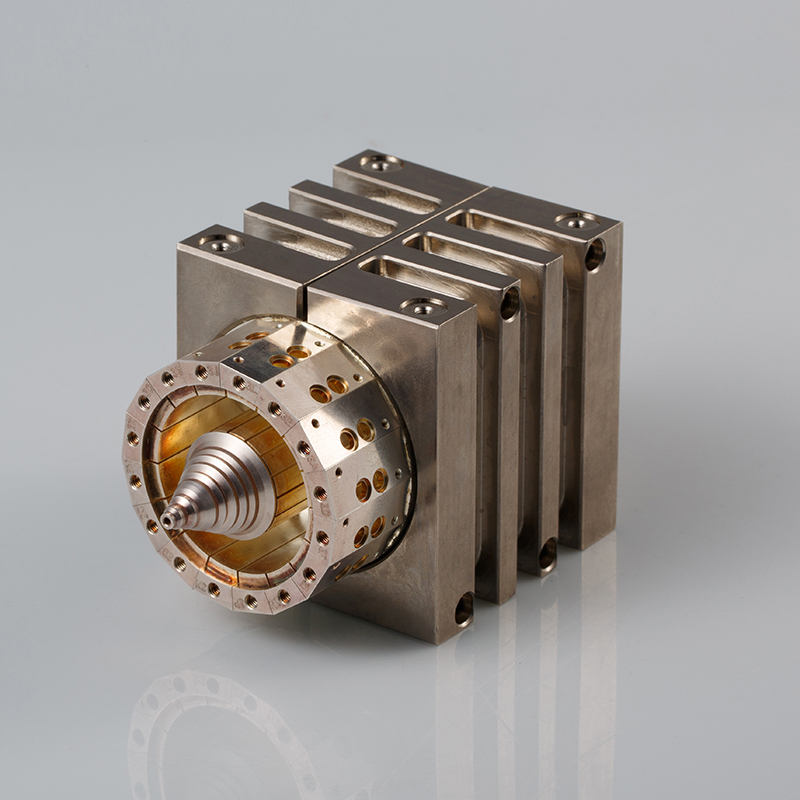

In the aerospace industry, where safety and performance are paramount, aluminum precision parts have become the cornerstone of technological advancements. From aircraft frames to critical engine components, the lightweight and corrosion-resistant properties of aluminum, combined with precision machining, have led to more efficient and safer flight. The growing significance of these parts in aerospace is evident in their ability to meet stringent quality and reliability standards.

Automotive: Driving Efficiency

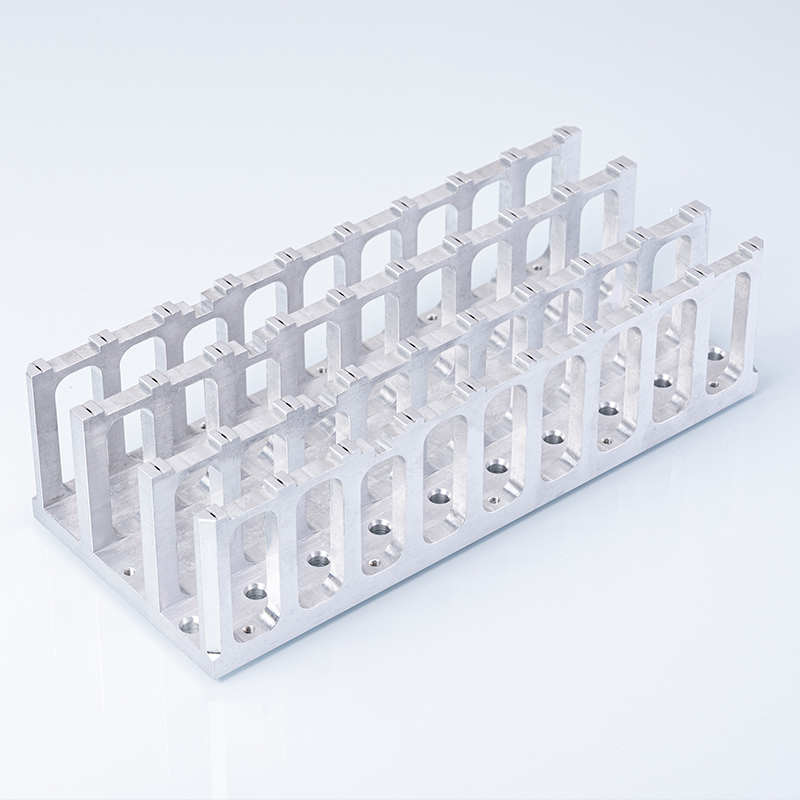

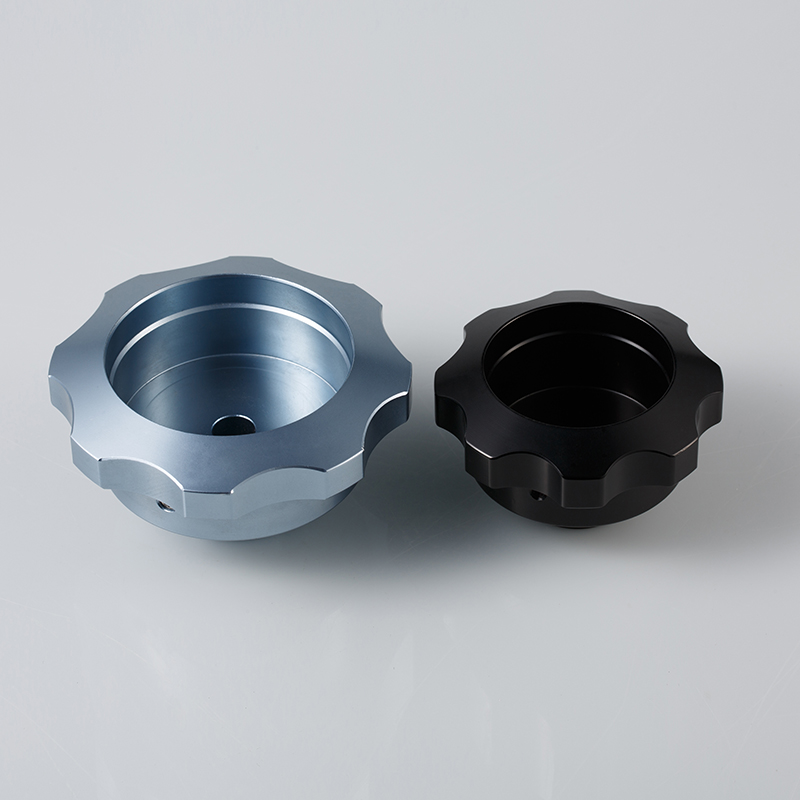

Within the realm of precision aluminum parts, there's a growing demand for tailored solutions. This demand is met by custom aluminum parts services, which specialize in delivering components that precisely match unique requirements. Whether for aerospace, automotive, or electronics, the precision aluminum part supplier plays a pivotal role in ensuring that the end product meets exacting standards.

Electronics: Shrinking the World

The electronics industry relies on miniaturization and precision, and aluminum precision parts have enabled the development of smaller, more powerful devices. From smartphones to high-performance computers, these parts facilitate the creation of compact, yet highly efficient electronic gadgets. This trend shows no signs of slowing down as technology continues to advance.

Medical Devices: Saving Lives with Precision

In healthcare, aluminum precision parts have made significant contributions to the development of life-saving medical devices. Precision machining ensures the reliability and accuracy of critical components used in devices like surgical instruments, diagnostic equipment, and implantable devices. The ability to manufacture these parts to exact specifications is essential for patient safety.

Conclusion

As we look to the future of manufacturing, it's clear that aluminum precision parts, including aluminum machining parts, and aluminum turned parts, are at the forefront of innovation. Their growing significance across industries underscores their versatility, precision, and adaptability. These parts have set new standards for manufacturing, driving progress in aerospace, automotive, electronics, healthcare, and more.

In a world where precision matters more than ever, aluminum precision parts have proven to be the cornerstone of excellence. As industries continue to evolve, we can only anticipate further breakthroughs and innovations that will redefine the significance of these remarkable components in the years to come.