There are several surface treatments that can be used for CNC machined aluminum parts. The type of treatment used will depend on the specific requirements of the part and the desired finish. Here are some common surface treatments for CNC machined aluminum parts:

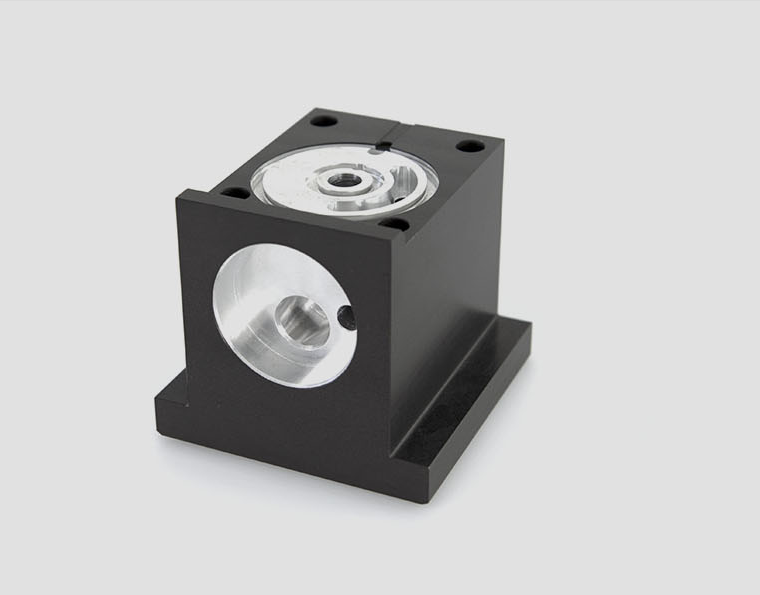

1. Anodizing / Hard anodized

This is a process in which an oxide layer is grown on the surface of the aluminum. Anodizing can provide a durable, corrosion-resistant finish that can be dyed to a variety of colors.Can be clear ,black ,red, blue, purple,yellow or any colors you need according to your design.

2. ALTEF (Teflon)

ALTEF(Teflon) is a type of surface treatment process used in CNC machined parts. It stands for Aluminum Teflon Electroless Nickel Plating, and it involves depositing a thin layer of electroless nickel on the surface of the aluminum part, followed by a layer of Teflon.

The ALTEF process is used to improve the wear resistance and reduce the friction coefficient of aluminum parts. The electroless nickel layer provides a hard, corrosion-resistant surface that improves the durability of the part, while the Teflon layer reduces the coefficient of friction between the part and other surfaces, improving the part's sliding properties.

The ALTEF process works by first cleaning the aluminum part to remove any impurities or contaminants. The part is then submerged in a solution containing the electroless nickel plating chemicals, which deposits a layer of nickel onto the surface of the part through an autocatalytic process. The nickel layer is typically around 10-20 microns thick.

Next, the part is submerged in a solution containing Teflon particles, which adhere to the nickel layer and form a thin, uniform layer of Teflon on the surface of the part. The Teflon layer is typically around 2-4 microns thick.

The result of the ALTEF process is a highly wear-resistant and low-friction surface on the aluminum part, which is ideal for use in high-performance and precision applications, such as aerospace, automotive, and medical industries.

3. Powder Coating

This is a process in which a dry powder is electrostatically applied to the surface of the aluminum and then baked to form a durable, decorative finish.

4. Chemical Polishing

This process uses chemicals to remove a small amount of material from the surface of the aluminum to create a smooth, shiny finish.

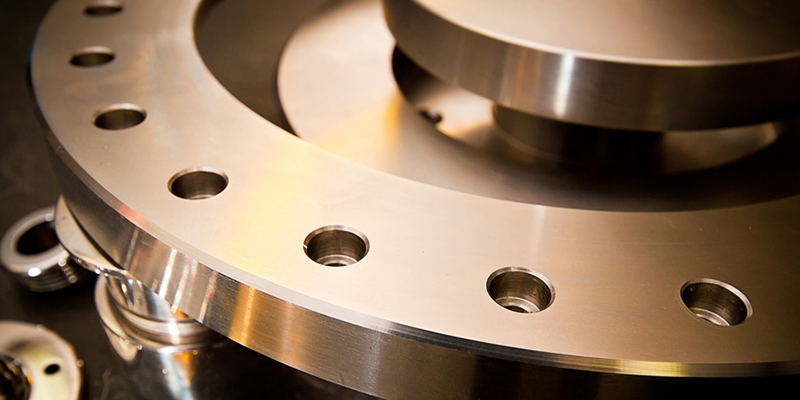

5. Mechanical Polishing

This process involves using a series of abrasives to remove material from the surface of the aluminum to create a smooth, shiny finish.

6. Sandblasting

This process involves using high-pressure air or water to blast sand or other abrasive materials onto the surface of the aluminum to create a textured finish.